what we've been working on:

Over the years, VeraErnest has completed a wide range of successful projects that have helped our clients achieve their goals and objectives.

Some of the notable projects we have completed include the development of a mobile thermal separation system for a major Oil and Gas Service Provider, the design and engineering of a pilot BioOil refinery, and the design and fabrication of a custom shaker skid. These projects are a testament to our ability to understand our clients' unique needs and provide them with tailor-made solutions that exceed their expectations.

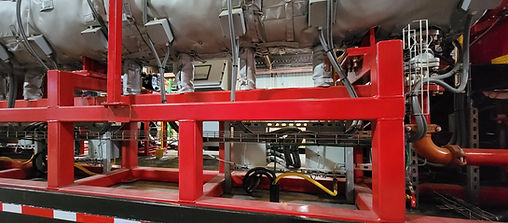

Thermal Processing Units

VeraErnest completed an extensive refurbishment of an earlier version of a client's proprietary waste treatment system package, transforming it to mimic the latest iteration of this product, bringing uniformity back to the client’s fleet.

VEI provided design enhancements/improvements for build and operability as a completely new mobile thermal processing unit was built.

Upon completion Factory Acceptance Testing was conducted at our facility and validated in the field by the customer.

This project included a 53 foot step deck

trailer with fully HVAC conditioned Control Room (MCC, PLC and VFD enclosures, UPS and HMI.

The main process area with Class Division hazardous area zoning comprised heaters, motors, pumps, heat exchangers custom designed and fabricated vessels, valve actuation and typical instrumentation allowing for automated PLC/HMI control.

Custom Mobile Workshop

Custom 20ft high cube Conex mobile workshop or secured spares storage unit designed and built to meet clients' unique needs.

Modules provide-

•space for spare parts and materials

•flammable substances cabinet

•work bench

•crane for heavy maintenance lifts

safe lockable cabinets to make sure your valuable tools and instruments don't go missing!

Cubility - Mobile Pilot Skid

From the initial concept renders, to engineering design details, to fabrication and paint, the Cubility Mobile Skid incorporates folding platforms, collapsible explosion proof lights, and pump and electrical control panel installation. For more info on this novel technology, visit: www.cubility.com

Enoverra - HTL Pilot

The Hydrothermal liquefaction (HTL) pilot project was received by VEI as a standalone pilot reactor system. VEI integrated PLC/HMI upgrades, a steel reinforced enclosure, piping and engineering improvements to create a working pilot unit that considers safety as the most important aspect of the high pressure, high temperature process.

Main components of this project include pumps with Variable Frequency Drives, PLC controlled PID solid state heaters, custom microprocessor controlled hydraulic pump, and processing constraints to maintain set point.

Valve Refurbishment & Run Testing

At our engineering and fabrication facility, we offer a comprehensive refurbishment and FAT testing service for Dome Valves, Spheri-Valves, and Roto-Disk Valves.

Our experienced technicians can disassemble valves to inspect, clean, and replace any worn or damaged parts.

We also provide a full FAT for operability, pressurized leak testing and cyclic bench top running for endurance testing as required.

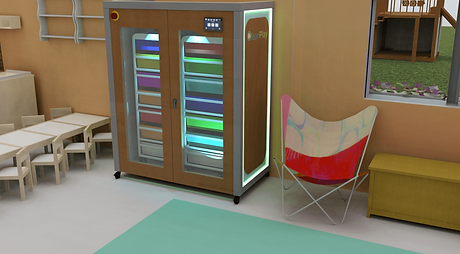

CleanPlay

CleanPlay is a technology developed by Vera Ernest engineers to use varying levels of concentrated ozone to eliminate surface bacteria from common items in the home, day care, gym, and entertainment facilities. The system was developed using 3D printed components, plasma ozone generators, and a customized smart control system using a tablet user interface with WiFi and Bluetooth capabilities.

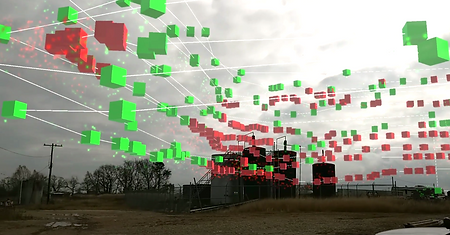

Augnear

Using Augmented and Virtual reality platforms, a tool was developed to visualize concentrations of hazardous or greenhouse gas and the direction in which the gas is flowing.

This allows for maintenance crews working on gas leaks to pinpoint the source to simplify troubleshooting.